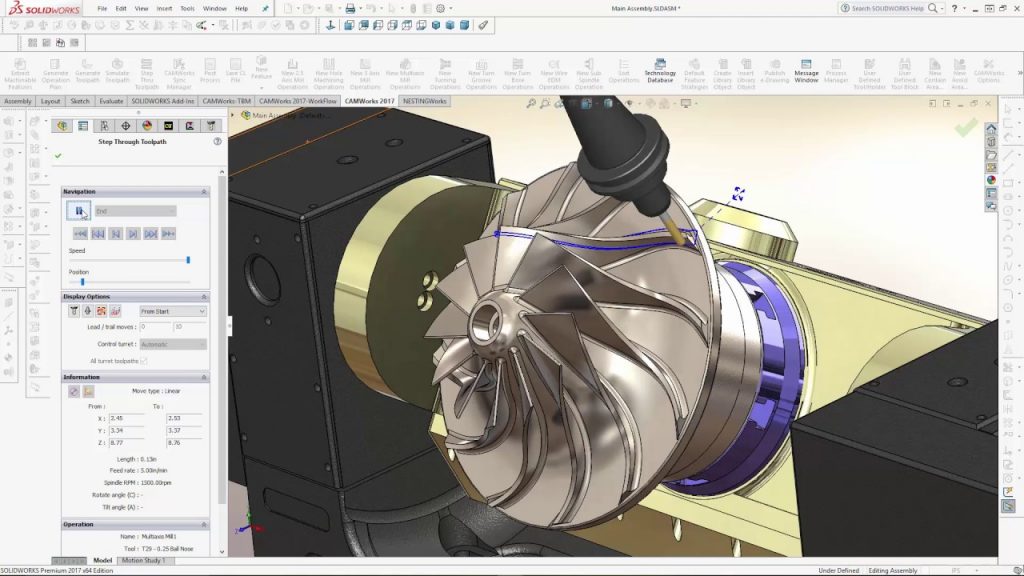

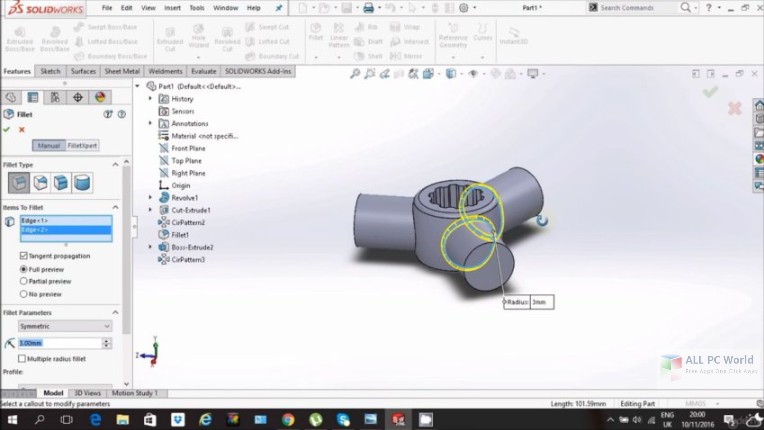

– Work with the same familiar user-interface ensuring a short learning curve – Use a single file for storing CAD and CAM data drastically reducing file management – Eliminate time-consuming file transfers using standard file formats such as IGES and STEP – Maintain associativity between the design model and the toolpaths ensuring that the latest changes in the design reflect in the toolpath CAM systems that are not integrated with CAD require revised parts to be re-exported, and in most cases updates to geometry must be made interactively.ĬAMWorks offers true associative machining automatically accommodating changes to the part model, which eliminates time consuming CAM system rework due to design updates.īeing integrated into the design environment, CAMWorks allows a user to: When complete, tool paths and other CAM information are stored in the Solid Edge model.Ĭhanges made to Solid Edge parts are immediately reflected in NC programs produced by CAMWorks. There is no need to export software to another format and import it into an NC programming tool. Although seven computer-aided manufacturing (CAM) software products have achieved so-called Gold Partner integration with SolidWorks, CAMWorks is the first such software to be seamlessly embedded within Solid Edge.ĬAMWorks for Solid Edge allows programmers to open a part file in native format and begin making a numerically controlled tool program immediately. In June 2013, Geometric Software released a version of CAMWorks integrated with Solid Edge, the value priced CAD system from Siemens PLM Software.

CAMWorks was first published as an add-in application for numerically controlled (NC) tool programming in SolidWorks in 1997.

0 kommentar(er)

0 kommentar(er)